The Process was developped from s. Experience industrial superiority with Fused Deposition Modeling FDM the only additive manufacturing technology that works with production-grade thermoplastics in the FDM 3D printer under a patented self-calibrated heated chamber.

Rapid Prototyping Fused Deposition Modelling And Laminated Object Manufacturing Youtube

Read our full fused deposition modeling guide here.

Https www solidconcepts com technologies fused deposition modeling fdm. Fused Deposition Modeling FDM Fused deposition modeling FDM is a additive manufacturin technology commonly used for modeling prototyping and production applications. And is therefore the first technology that a newbie in additive manufacturing is made familiar with. Material choices range from ABS Diran Durus Nylon TPU Ultem and more plus clear and biocompatible properties.

Parts built with production-grade thermoplastics last for years performing like traditional machined parts under real-world conditions make them the best buy 3D Printer in India for your investment. Fused Deposition Modeling FDM or Fused Filament Fabrication FFF is an additive manufacturing process that belongs to the material extrusion family. FDM 3D printing belongs to the material extrusion family.

The Fused Deposition Modelling FDM process constructs three-dimensional objects directly from 3D. Form and fit testings. Wide-format FDM is applicable to both prototyping and production-grade parts giving customers a wide array of options for.

Selective Laser Sintering SLS. Fused Deposition Modelling FDM based Stratasys 3D Printer systems transform 3D CAD files into functional prototypes manufacturing tools and end-use parts. Fused Deposition Modeling FDM sometimes called Fused Filament Fabrication FFF.

The term Fused Deposition Modeling and its abbreviation FDM are trademarked by Stratasys. Scott Crump in the 1980s and commercially used in the 1990s. Fused Deposition Modeling or FDM is a 3D printing technology that builds parts layer-by-layer by heating and extruding engineering-grade thermoplastics.

This technology represents the widest installed base of 3D printers globally. Fused Deposition Modeling FDM Technology is a powerful Stratasys-patented additive manufacturing method. It involves depositing melted filament on a build platform to create a finished part.

Industrial-grade Fused Deposition Modeling FDM delivers robust precise thermoplastic parts quickly. FDM filaments typically come in a spool and the material is fed into an extruder. What is fused deposition modeling FDM.

Scott and Lisa Crump as a technology for 3D printing where a material is extruded out of a nozzle and creates a 3D object layer by layer. The Fused Deposition Modeling FDM applies thermoplastic materials in layers through a melt layer process. Each layer is created by extruding material from a nozzle to produce 3D objects.

FDM Technology uses the same tried and tested thermoplastics found in traditional manufacturing processes. Fused deposition modeling is a 3D printing technology that melts plastic to create a 3D object layer by layer. Fused Deposition Modeling or FDM 3D printing technology is the perfect additive manufacturing process to create parts that are strong and durable with special material properties like heat chemical and flame and toxicity resistance.

FDM is the most widely used 3D Printing technology. Fused Deposition Modeling FDM Technology is a powerful Stratasys-patented additive manufacturing method. FDM materials have excellent mechanical properties and quality making FDM printing suitable for prototyping production tooling and manufacturing.

Fused deposition modeling FDM is a 3D printing technology also known as additive manufacturing commonly used for modeling prototyping and production applications. 05 lower limit 05 mm. FDM stands for Fused Deposition Modeling sometimes also known as Fused Filament Fabrication.

You can use a number of thermoplastic 3D filaments for FDM printing such as TPU PLA ABS and others. It represents the largest installed base of 3D printers globally and is often the first technology people are exposed to. With FDM you can create jigs.

Fused Deposition Modeling FDM 3D printing technology is used to produce models in plastic materials such as ABSThe principle of FDM is simple. Types of 3D Printing Technology. Fused Deposition Modeling FDM Fused Deposition Modeling is the most accessible 3D printing technology with FDM 3D printers by far the cheapest to pick up for new makers.

FDM builds concept models functional prototypes and end-use parts in standard engineering-grade and high-performance thermoplastics. Fused Deposition Modeling was invented and patented in 1989 by S. For applications that demand tight tolerances toughness and environmental stability - or specialized properties like electrostatic dissipation translucence biocompatibility VO flammability or FST ratings - theres an FDM thermoplastic that can deliver.

Thermoplastic filament PLA ABS PET TPU. FDM is a 3D printing technology in which a thermoplastic material is extruded layer by layer to build durable parts. The term Fused Deposition Modeling and its abbreviation to FDM are trademarked by Stratasys.

An alternative term for the process is Fused Filament Fabrication. FDM technology allows you to use engineering-grade thermoplastics that are ready for harsh. FDM technology is used to build concept models functional prototypes and end-use parts in standard engineering-grade and high-performance thermoplastics.

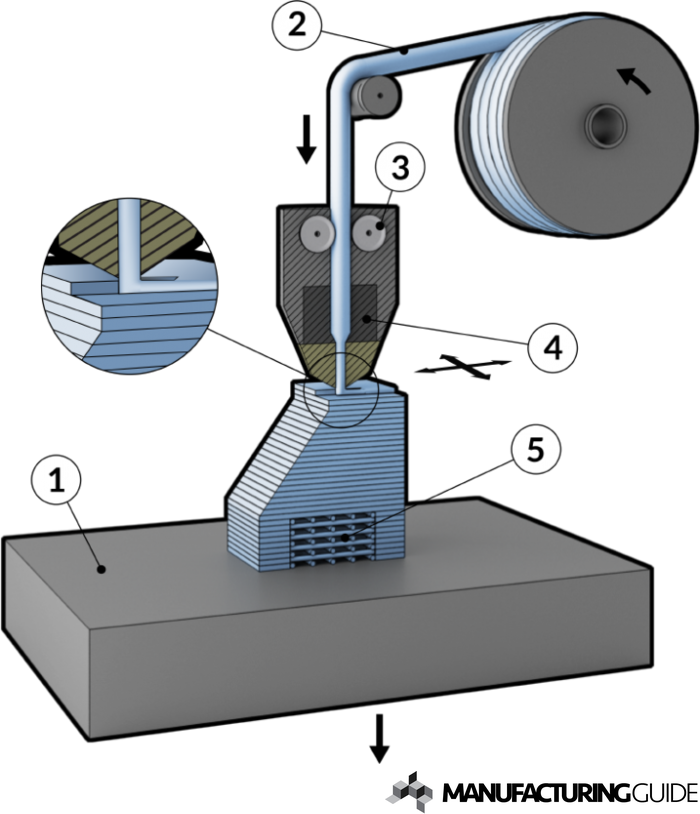

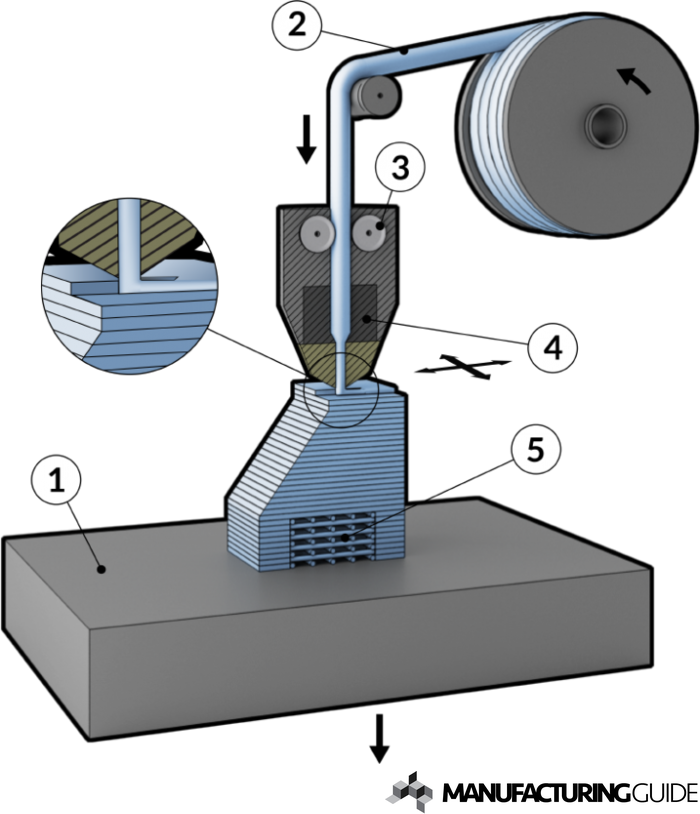

Fused Deposition Modeling Fdm Find Suppliers Processes Material

Fused Deposition Modeling Fdm Find Suppliers Processes Material

Material Extrusion And Its Types Fused Deposition Modelling Fff

Fdm Fan Blade Hand Finished With Cosmetic Paint Fused Deposition Modeling Fan Blades Model